CoreFlex™ Methane Barrier & Waterproofing System

System Description

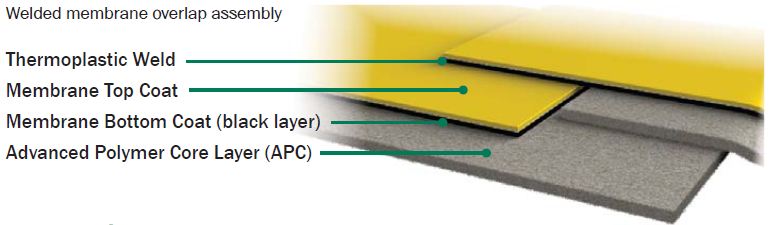

CoreFlex is a fully-weldable, flexible membrane liner which functions as both a methane gas barrier and a high-performance waterproofing (hydrostatic conditions) membrane. CoreFlex features a heat welded thermoplastic membrane with the industry’s heaviest reinforcement plus Active Polymer Core (APC) Technology.

Benefits of Utilizing the CoreFlexTM System

- Active sealing waterproofing membrane

- Superior puncture resistance, tensile and tear strengths

- Methane Barrier approval in City of Los Angeles (LARR)

- Eligible for the HydroShield* Quality Assurance Program

More About CoreFlexTM Active Polymer Core (APC) Technology

CoreFlex features a thermoplastic membrane integrally bonded to a proprietary Active Polymer Core (APC) Technology layer that works together to ensure superior waterproofing protection for your project

- If the thermoplastic membrane component is ever punctured or damaged, the APC layer is engineered to actively control water ingress by swelling to produce a reliable seal at the breach.

- To maximize performance, the APC layer is installed direct to the concrete to be waterproofed, thus preventing water ingress into the structure.

- The APC geotextile layer provides a protective cushion to decrease the potential of the thermoplastic membrane being punctured from irregular substrate surface texture.

- Each membrane overlap seam utilizes a combination of a passive and active barrier technologies by use of a conventional weld and an overlap assembly to assure water-tightness. and enhanced seam performance.

- No other membrane offers APC technology.